Enhanced cytocompatibility and mechanical properties of electron beam melted Ti-6Al-4V by friction stir processing

Abstract

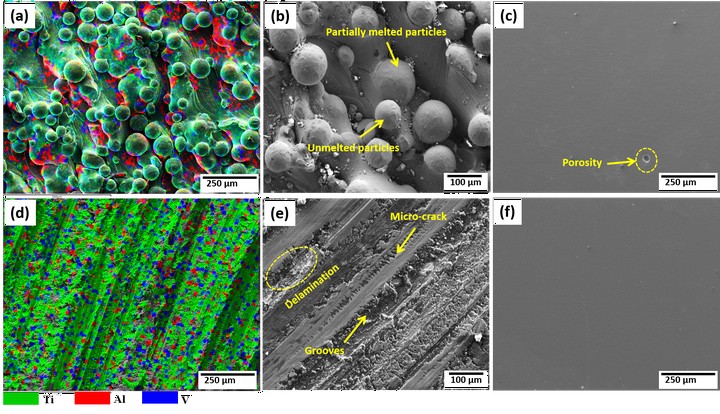

Electron Beam Melting (EBM) is an emerging additive manufacturing technique for the fabrication of titanium alloy Ti-6Al-4V for orthopedic applications. Here, a hybrid manufacturing technique viz. EBM with Friction Stir Processing (FSP) has been proposed to enhance implant surface properties. The surface modification using FSP reduces the roughness generated by the EBM technique from ~44.77 μm to ~15.82 μm. Simultaneously, FSP improves the biological and mechanical properties of the Ti-6Al-4V substrates. The roughness, wettability, amounts of ions released, and surface microhardness were measured to analyze the stability of the substrates. The effect of the hybrid processing strategy on cell viability was tested against mouse fibroblast cells NIH3T3 through MTT assay, and we found that the friction stir processed substrate (EBM-F) showed the highest cell viability. The EBM-F surface displays a two-fold increase in the cell-viability as compared to the unprocessed EBM surface after 24 h of cell-seeding. The FSP substrate allows human cervical cells HeLa to adhere onto its surface while selectively preventing the attachment of E.coli bacterial cells. These observations towards cells signify biocompatible surface characteristics of the FSP EBM substrate.