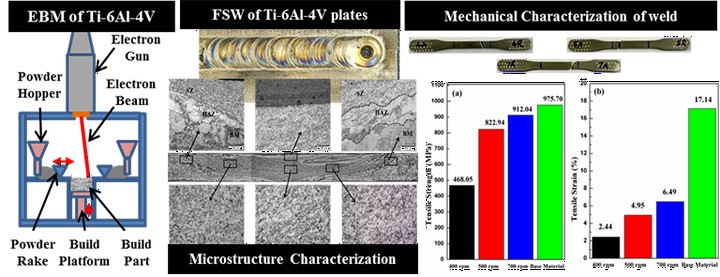

Friction stir welding of additively manufactured Ti-6Al-4V: Microstructure and mechanical properties

Abstract

Additive manufacturing of titanium alloy Ti-6Al-4V has significantly increased over the past few years, primarily due to its broad application over the conventional manufacturing process for complex and near net shape production. However, difficulties arise while printing complex and huge structures and therefore, the components need a suitable joining process. We study the feasibility of friction stir welding of Ti-6Al-4V plates made by electron beam melting, performing both microstructural and mechanical analysis. Microstructures for all the welds reveal lamellar (α+β) phase and very fine equiaxed α grain with the prior β phase at grain boundaries in the stirred zone. Microhardness at different depths of the joint is measured and the strength of the joint is determined using a tensile test. The results obtained prove the feasibility of the process and provide the necessary processing conditions.