Corrosion Behavior of Aluminum Surface Composites with Metallic, Ceramic, and Hybrid Reinforcements Using Friction Stir Processing

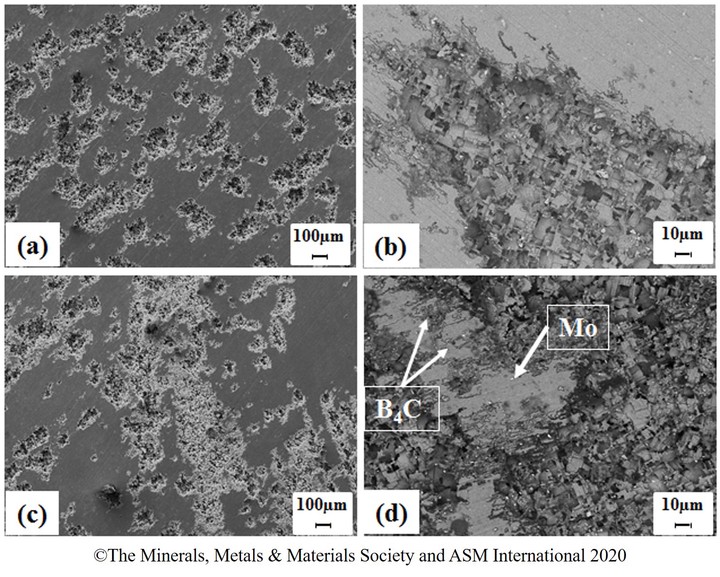

Post-corrosion SEM micrographs of Al-B4C-Mo samples

Post-corrosion SEM micrographs of Al-B4C-Mo samples

Abstract

The study focuses on the effect of mono and combined addition of metallic and ceramic reinforcement particles on the microstructural and corrosion behavior of surface composites fabricated by friction stir processing. Molybdenum, possessing higher corrosion resistance compared to aluminum, is used as the metallic reinforcement, and boron carbide is used as ceramic reinforcement. Combined addition of boron carbide and molybdenum is used to study the effect of hybrid reinforcement on the corrosion behavior of Al 1050 surface composites. The effect of friction stir processing and reinforcement type on the electrochemical behavior of surface composites is analyzed through potentiodynamic polarization and impedance analysis. Reinforcement particles distributed on the Al matrix through friction stir processing affect the pitting corrosion behavior of surface composites. Post-corrosion microscopy analysis is carried out to understand the effect of the reinforcement particles on the pitting corrosion. The surface composites fabricated are free from any intermetallics. Surface composites with second processing pass showed better corrosion resistance due to more homogeneously distributed finer Mo particles in Al-Mo surface composites. Mono-reinforced surface composites exhibited an increase in the corrosion resistance, whereas the combined addition of reinforcements induced more galvanic effect in the surface composite leading to more severe corrosion.