Microstructural Modification and Surface Hardness Improvement in Al-Mo Friction Stir Surface Composites

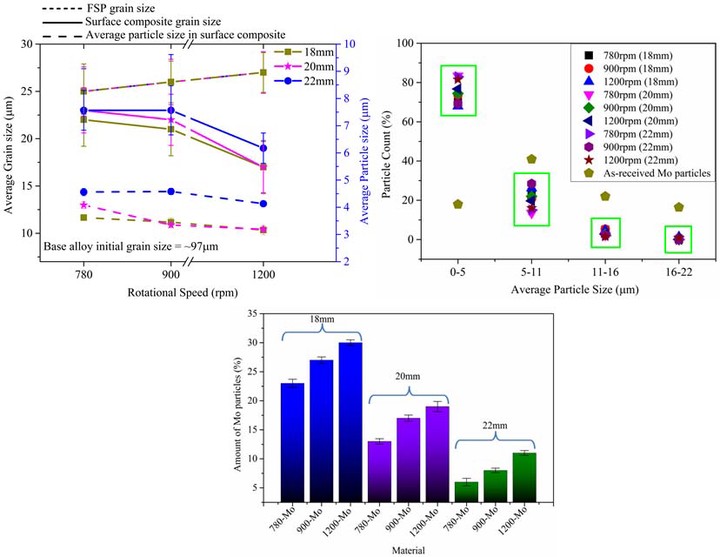

Grain size and particle distribution in surface composites as function of RPM

Grain size and particle distribution in surface composites as function of RPM

Abstract

Molybdenum-reinforced aluminum matrix surface composites have been fabricated using friction stir processing. The Mo reinforcement results in an increase in the hardness and a decrease in the grain size. The Mo particle size and its dependence on the tool rotational speed are important for fabrication of highperformance composites. However, the effect of the tool rotational speed on microstructure, particle size and distribution, and hardness is not known. Here, we present microstructural and microhardness analysis of Al-Mo surface composites for varying tool rotational speeds. Increase in tool rotational speed results in reduced particle size, better particle distribution, and reduced grain size. The surface hardness also increases with an increase in the tool rotational speed.