An ultra-high strength conducting diamond composite

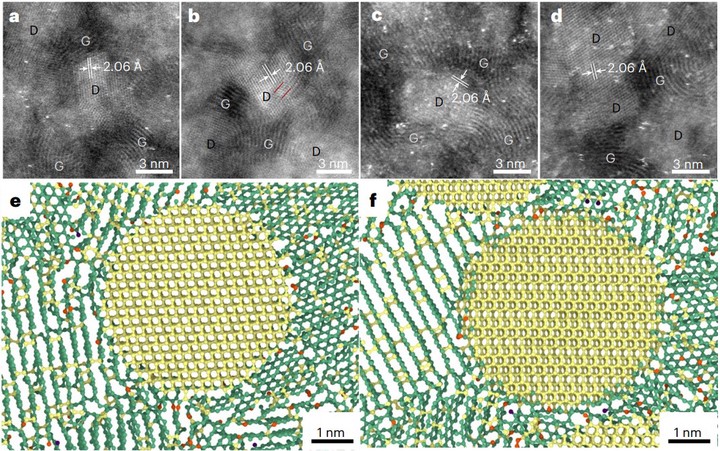

a–d, Atomic-resolution HAADF-STEM images, revealing the complex interface structures with random, self-matching sp2 or sp3 bonding. D and G represent the regions of ND and DMG, respectively. The {111} d spacing of diamond is specified. Twin boundaries are indicated by red lines. e,f, Simulated atomic structure at the interface between ND and DMG. The red, green and yellow atoms are of sp, sp2 and sp3 hybridizations, respectively. The yellow nano diamonds have a size of ~5 nm. Source: https://doi.org/10.1038/s41563-022-01425-9

a–d, Atomic-resolution HAADF-STEM images, revealing the complex interface structures with random, self-matching sp2 or sp3 bonding. D and G represent the regions of ND and DMG, respectively. The {111} d spacing of diamond is specified. Twin boundaries are indicated by red lines. e,f, Simulated atomic structure at the interface between ND and DMG. The red, green and yellow atoms are of sp, sp2 and sp3 hybridizations, respectively. The yellow nano diamonds have a size of ~5 nm. Source: https://doi.org/10.1038/s41563-022-01425-9

Development of composite materials is primarily to cater the diverse requirement of problem statement, specific to an application. Over the years, several composites based on various matrix materials such as metal, ceramic, and polymer, have been developed in combination with various reinforcements. Ceramic, generally alone being a good refractory material with high compressive strength, ceramic matrix composites (CMCs) become a good option for applications that involve ultra-high temperatures and stress over metal matrix composites (MMCs). However, despite having properties such as high-temperature stability, wear resistance and excellent hardness, etc., their applicability gets restricted to applications that demand good electrical conductivity because of their electrically insulating nature. Efforts are being made continuously to incorporate or enhance the electrical conductivity of these CMCs though introducing various secondary conducting phases in the ceramic matrix as dopants. But, the limited diffusivity of the ceramic matrix caps the amount of dopant being introduced.

Researchers from Aalborg University, Denmark; Yanshan University and Tsinghua University, China, have reported a carbon-carbon-based electrically conductive ceramic composite that yields a massive compressive strength of 54Gpa with an electrical conductivity of 670–1,240 S m–1. With This exceptionally good composite uses only two different forms of carbon allotropes i.e., disordered multilayer “graphene” (DNG) and nano-“diamonds” (ND). The approach was to exploit the structure-property relation of these allotropes through an in-situ partial transformation of amorphous conductive graphite into hard nano-diamonds precipitates resulting in a composite that yields ultra-high strength and electrical conductivity at the same time.

The graphite to diamond transformation does not follow the traditional route; instead, a local diffusion-driven growth and rearrangement of carbon atoms, lead to the formation of ultrafine nano -diamonds precipitates which has been established through molecular dynamic simulation and high resolution atomic interfacial structures. Interfacial mixed bond hybridization also strengthens the phase transformation mechanism of graphite to diamonds. Transformed diamonds and disordered graphene interfaces are reported to be incoherent, i.e., a non-uniform and irregular connection between phases, which plays a key role towards the development of such excellent properties. With such robust strength and electrical properties, the developed composite can be deployed as an ultrastrong conductive indenter in nanomechanics, static-free bearings, anti-static substrates and components. The work has been submitted for a provisional patent application entitled ‘Conductive diamond/amorphous carbon composite material having high strength and process for preparing the same’ by Yanshan University

For more details read: https://doi.org/10.1038/s41563-022-01425-9